How Nike Uses 3D Apparel to Move Faster Than Its Competitors

For years, speed in fashion was about logistics. Who could manufacture faster. Ship faster. Distribute faster.

Today, the real speed advantage happens before anything is ever made.

Nike has been quietly investing in 3D apparel workflows for years — and the payoff isn’t just better visuals. It’s faster decision-making, fewer physical samples, and tighter alignment between design, marketing, and product teams.

Here’s what Nike is doing differently — and why more apparel brands are moving in the same direction.

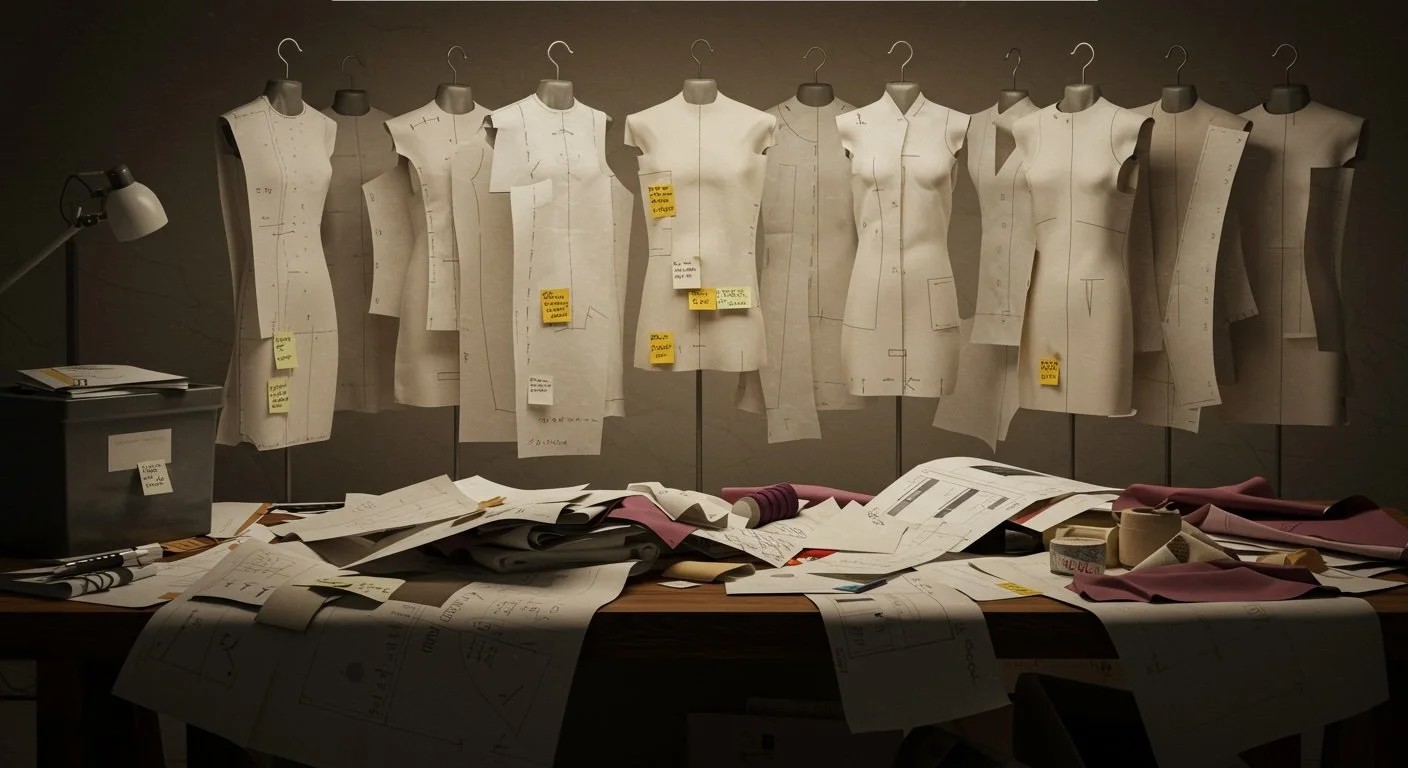

The problem traditional apparel development creates

At Nike’s scale, traditional apparel development introduces friction at every stage:

Physical samples take weeks or months

Design feedback loops are slow

Marketing assets lag behind product readiness

Late-stage changes are costly

When hundreds of SKUs are in development simultaneously, even small delays compound across an entire season.

Nike’s goal wasn’t just better visualization. It was earlier clarity.

Nike’s shift to 3D apparel design workflows

Nike has openly discussed its move toward digital product creation (DPC), where apparel is built digitally before any physical sample exists.

In a 3D apparel workflow:

Garments are created from real patterns

Fabric behavior is defined digitally

Fit and drape are evaluated virtually

Colorways and variations are explored without resampling

Instead of waiting weeks to see a design physically, teams can evaluate it in hours. This is a foundational shift in how apparel teams work.

Read about Zara’s 3D Revolution (another global fashion brand leveraging 3D earlier in development)

Why 3D apparel matters beyond design teams

A common misconception is that 3D clothing tools are only for designers.

Nike treats 3D apparel assets as cross-functional tools.

Faster internal alignment

Photorealistic 3D garments reduce interpretation issues by clearly showing:

Silhouette and proportions

Fabric behavior

Construction details

This minimizes miscommunication between design, development, and merchandising teams.

Marketing content can start earlier

Because 3D apparel assets exist earlier in the lifecycle, marketing teams can:

Produce launch visuals sooner

Test colorways before samples arrive

Build campaigns in parallel with development

High-quality 3D clothing renders allow brands to plan launches without waiting on final samples.

Learn more about 3D Apparel & Clothing Rendering Services

Fewer physical samples and less waste

Every physical apparel sample requires:

Time

Shipping

Labor

Materials

3D apparel design allows brands to:

Eliminate early design-round samples

Catch fit and construction issues sooner

Reduce unnecessary waste

For large brands, the efficiency gains scale quickly.

What smaller apparel brands can learn from Nike

You don’t need Nike’s budget to apply Nike’s thinking.

The key insight is simple:

Better decisions happen when teams can clearly see the product earlier.

For growing fashion, performance, and outdoor brands, photorealistic 3D clothing renders provide that clarity by:

Visualizing garments from real patterns

Accurately representing materials

Supporting internal reviews and approvals

Creating launch-ready visuals before production

This reduces uncertainty without replacing physical garments entirely.

Check out our Ultimate Guide to 3D Clothing Renders for Fashion Brands.

Why many brands struggle when adopting 3D clothing

Not every attempt at 3D apparel succeeds.

Brands often walk away disappointed because:

Garments look stiff or artificial

Fabric behavior feels inaccurate

Fit appears incorrect

Renders aren’t usable for marketing

This usually isn’t a software issue. It’s an execution issue.

Believable 3D clothing renders depend on:

Clean pattern data

Proper fabric simulation

Accurate lighting and shading

Real-world garment knowledge

Without these, trust in the visuals breaks down.

The real advantage of high-quality 3D apparel renders

Nike doesn’t benefit from 3D apparel simply because it uses the technology.

They benefit because their 3D garments are accurate enough to make decisions from.

That’s the standard.

When 3D clothing renders are good enough to:

Replace early samples

Support line planning

Power sales and sell-in decks

Anchor product launches

They become decision-making tools, not just visuals.

That’s the same benchmark we apply when creating 3D apparel renders for fashion, performance, and outdoor brands.

The larger shift in apparel and fashion

Zara demonstrated how 3D accelerates fast fashion. Nike shows how it scales across global performance and lifestyle brands.

The pattern is consistent:

Faster feedback

Earlier alignment

Fewer wasted development cycles

As timelines compress and margins tighten, more apparel brands are realizing that meaningful gains happen before production begins.

The Future

The shift to 3D apparel design isn’t just a trend—it’s a smarter, faster, and more sustainable way for brands to bring ideas to life. From reducing physical samples and waste to enabling sharper marketing visuals and cross-team collaboration, high-quality 3D renders are proving their value across every stage of apparel development.

At VM, we specialize in creating photorealistic 3D clothing renders for some of the world’s leading brands. Our team blends cutting-edge technology with a deep understanding of fabrics, textures, and brand aesthetics, helping companies visualize collections before a single garment is sewn. Whether it’s for design approval, marketing campaigns, or e-commerce, our renders make it possible to iterate faster, communicate more clearly, and launch with confidence.

As more brands embrace 3D workflows, the question isn’t whether to adopt them—it’s how quickly you can start leveraging them. High-quality 3D renders are no longer just a design tool; they’re a competitive advantage.

Interested in working with us? Join our waitlist.